BL3 Automation Solutions

Complete control, even in motion.

At Okolab, we understand the import role that live-cell, high-content screening (HCS) plays in areas of research such as drug-discovery. At times, a dedicated all-in-one HCS solution cannot offer the imaging specifications or modality required to collect the data needed for a screen.

Imagine taking the microscope modality of your choice and automating it for live cell HCS, you can with the help of BL3 Automation Solutions. Over the past several years, we’ve adapted our established incubation technology to be amenable to the operation of robotic handling systems for custom HCS applications that go beyond the norm. Take all of the ground-breaking technology of the BL3 incubation system and apply it to your unique, automated HCS solution.

Documentation

Brochure

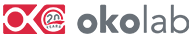

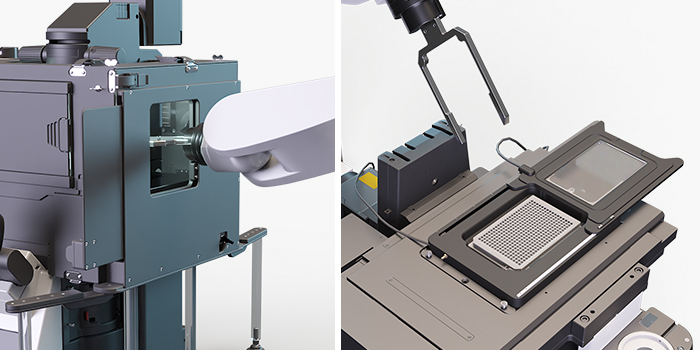

Synchronized Motorization

Okolab automated enclosures are equipped with motorized cage door and microenvironment lid mechanisms to allow access of a robotic plate loader to the stage area of a traditional microscope system.

The operation of these mechanisms is designed to integrate with your robotics control software, allowing seamless synchronization of movement between the of movement the robotic loader and the incubator.

Automation is available for cage and stagetop incubation configurations.

Precision repositioning

To ensure maximum spatial/XY reproducibility between time points, automated stage top incubators and microenvironment chambers (cage) are equipped with a motorized plunger mechanism to set each plate in the same ‘home position’ each and every time.

Further, an integrated load sensor detects the presence or absence of a plate and relays it to your robotic equipment, ensuring seamless operation and providing a ‘checkpoint’ for the automation process.

Auto-Refill Humidity Module

Certain high-content applications can take days or even weeks to complete. Traditional incubation systems across the board use humidity control modules that require a water reservoir to be refilled frequently (every 1-3 days), which can be problematic if the water runs out at an inopportune time.

Our automated humidity system maintains an adjustable relative humidity between 50-95% for weeks at a time without user-intervention thanks to automated refilling.

Never worry about running out of water again.

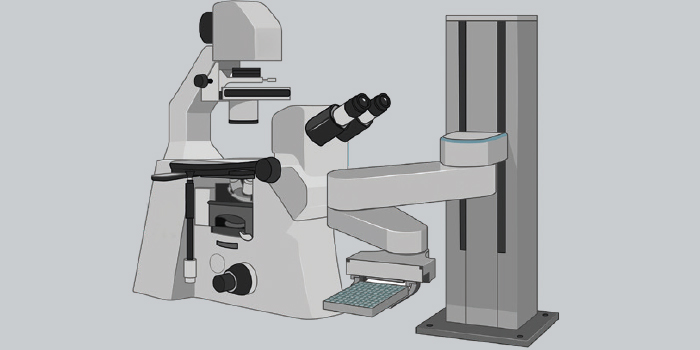

Fully Incubated Plate Hotel

Designed to be compatible with your robotic loader, this enclosure provides a storage area for multiple plates (customizable) with gas, humidity, and temperature control for plates between sampling points, ensuring stable incubation throughout the screening process.

Custom solutions available.

At Okolab, we take pride in our ability to create custom solutions uniquely suited for our biotech customers’ most demanding applications. Any of the above solutions can be custom-made or modified to best fit your automated workflow.

Have an incubation need for your automated system that isn’t listed here?

Whether it is for custom-designed, heated enclosures for non-standard setups or for specialized gas control requirements, let us design and build it for you.