BL3 Cage Incubator

Complete control where it matters most.

Live cell incubation, especially of mammalian cell lines, requires careful control of three crucial elements: Temperature, humidity, and CO2 concentration. Real-time monitoring and feedback of each of these elements has been introduced for each of these elements over time, but never for all three in a single product, until now.

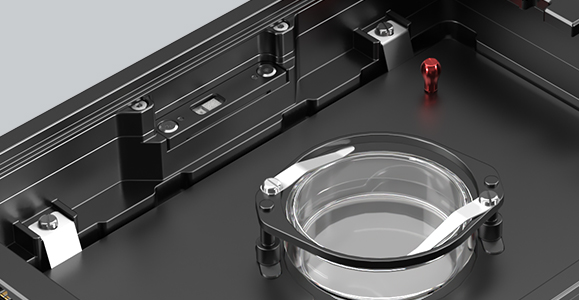

The BL3 is the first microscope incubation solution to provide closed-loop feedback control of temperature, humidity, and gas composition simultaneously; further, this feedback happens where it is most vital, at your sample.

Documentation

Brochure

For 20 years, Okolab has been a market leader provider of innovation for live cell imaging, the BL3 is the culmination of our experience with live cell imaging experts across the world over this time; offering the most complete, doubt-free live cell incubation solution available today. Because we want you to focus on your science, not your incubator.

New BL3 Cage Incubator Features:

- In-chamber feedback of CO2, Humidity, and Temperature level: Ensures desired experimental conditions at the sample, where it matters most

- Optimized temperature feedback system: new integrated temperature sensor continuously monitors temperature at the sample and ensures stable and uniform temperature, even when ambient temperature changes

- Efficient, ductless dual heater design: gets to temperature 50% faster while also reducing system footprint, save time and space

Complete, in-chamber feedback.

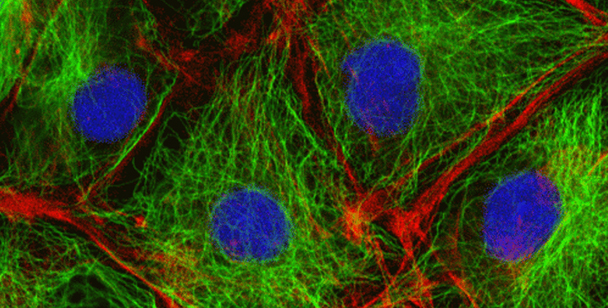

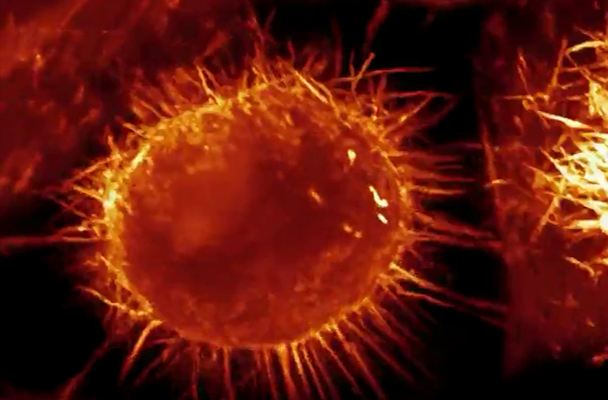

An example of why in-chamber feedback is important.

Traditional incubation systems with digital CO2 mixers sample CO2 concentration at the source, the mixer itself, where it is later routed to the live cell chamber. In theory, this should produce an environment within the chamber that matches the defined CO2 setpoint of the mixer; in reality, this is not always the case.

The reality is that in-chamber values of CO2 can differ significantly from the setpoint of an externally monitored digital mixer; usually due to some restriction of airflow or excessive leakage of CO2-mixed air from the chamber. In some cases, the loss of air to (or from) the chamber is severe enough to cause experimental failure.

Some common causes for this, observed multiple times in the field, are the following:

- an improperly secured lid on the microenvironment chamber

- loose connections or kinks in air tubing downstream from the mixer

- improper placement of sample or gaps between the sample carrier (dish, slide, etc) and the microenvironment chamber sample insert

- leaving a position on a multi-sample insert open to ambient air

By bringing feedback inside the chamber, the BL3 ‘sees’ what no other live cell chamber today can, ensuring accurate and stable conditions right from the start of your experiment, right where your experiment is happening.